TDS and Water Hardness: What We Need to Know

Water plays a crucial role in dairy processing, influencing not only the quality of the final product but also the efficiency of production. Whether you’re standardizing milk, cleaning equipment, or ensuring water safety, understanding the properties of water—such as hardness and Total Dissolved Solids (TDS)—is essential. This guide delves into these critical aspects and their significance for the dairy industry.

Understanding Water Hardness

Water hardness refers to the concentration of dissolved calcium and magnesium salts in water. It impacts cleaning, foaming, and even the taste and quality of milk. Below is a table that categorizes water hardness levels for easy reference.

Hardness Levels Table:

| Type of Water | ppm Range | gpg Range |

| Soft Water | 0–60 | 0–3.5 |

| Moderately Hard Water | 61–120 | 3.6–7 |

| Hard Water | 121–180 | 7.1–10.5 |

| Very Hard Water | 180+ | 10.5+ |

TDS Levels and Their Importance

Total Dissolved Solids (TDS) measure the total concentration of dissolved substances in water, including minerals, salts, metals, and organic matter. Here’s a table summarizing the ideal TDS levels for different applications

| Application | Ideal TDS (ppm) |

| Drinking Water | 0–500 |

| Milk Standardization | <300 |

| Aquariums | 50–500 |

| Industrial Applications | 1–10 |

Relationship Between TDS and Hardness

While TDS and hardness are related, they are not the same. Hard water contributes to higher TDS levels due to the presence of calcium and magnesium salts. However, high TDS does not always mean hard water, as other dissolved solids like sodium or potassium may increase TDS without contributing to hardness.

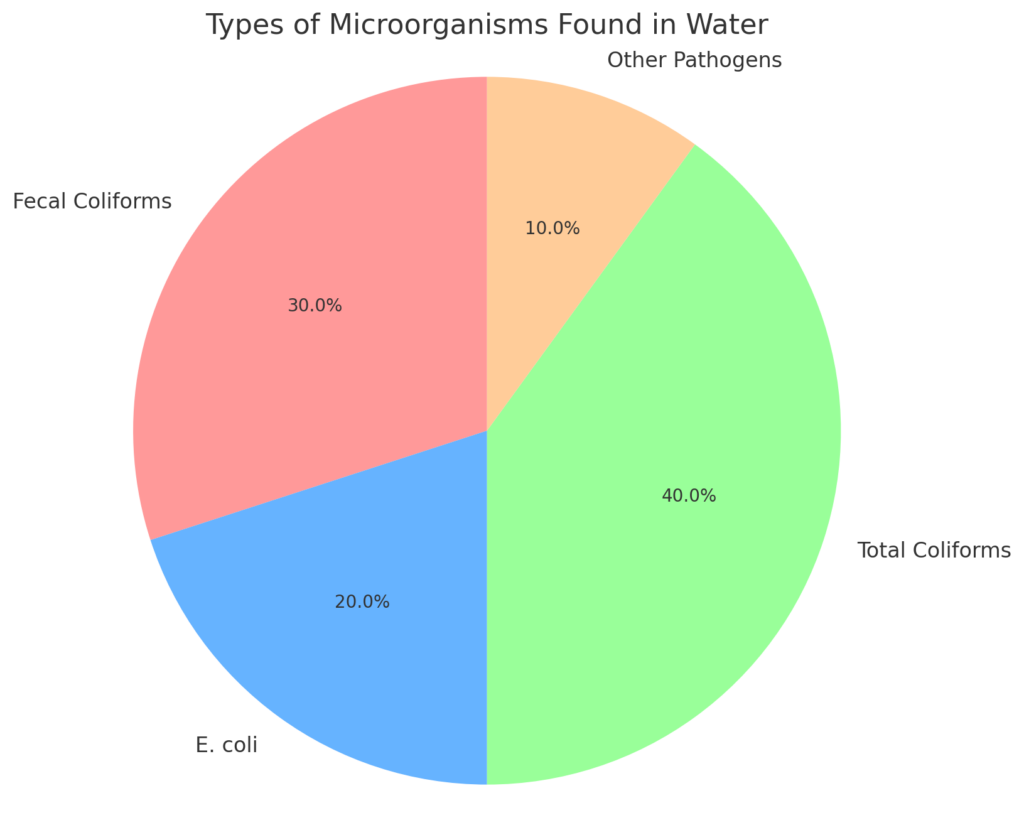

Microorganisms in Water and Their Growth

Even though water doesn’t inherently contain nutrients, microorganisms like coliforms can thrive under certain conditions. These conditions include the presence of organic matter, warm temperatures, and stagnant water. Here’s a breakdown of common microorganisms in water.

| Type of Microorganism | Percentage Contribution |

| Fecal Coliforms | 30% |

| E. coli | 20% |

| Total Coliforms | 40% |

| Other Pathogens | 10% |

How to Treat Water for Dairy Use

To ensure the safety and quality of water used in dairy operations, proper treatment is essential. Depending on the water’s hardness and TDS levels, different treatment methods can be applied.

1. For Temporary Hardness: Boiling the water precipitates bicarbonates as carbonates, softening the water.

2. For Permanent Hardness: Use an ion-exchange process or reverse osmosis to remove non-bicarbonate salts.

3. For Microbial Safety: Disinfect water using chlorine, UV treatment, or ozonation.

Conclusion

Water quality is a cornerstone of dairy processing, influencing every aspect from milk standardization to equipment maintenance. Understanding the relationship between hardness, TDS, and their impact on milk can help ensure better products and smoother operations. At Dairy is Food, we emphasize the science behind dairy, helping you understand how every component, even water, plays a crucial role in delivering quality dairy products.