How whiskey is made: Overview of the process

Whiskey is both a simple product and an endlessly enigmatic drink. People over the ages has perfected the art of whiskey with the subtle variations in the processes evolved through the ages accidentally or through development. It is made from grain (though a country like India does from molasses), water, and yeast, and yet the spectrum of aromas and tastes that emerge from a mature whiskey can be wondrous, enticing and beguiling.

How can such basic ingredients produce such an array of flavours? The answer lies in all the small variations in the whiskey-making processes.

1.Selection of grains

The first step is choosing the grain. Barley is the most commonly used ingredient in whiskey-making. It is the sole grain in Scotch malt, and a percentage of malted barley is used in almost all whiskey.

Corn, wheat, and rye are the other grains used in whiskey-making. Corn is the principal grain for making bourbon and Tennessee whiskey, and rye grain is the key ingredient in rye whiskey.

The term “grain whiskey” refers to whiskey made principally from grains other than barley for primary use in making blended whiskey. The main grains used for making grain whiskey are either corn or wheat.

2.Malting

Barley goes through a malting process to activate enzymes and maximize its starch content, which is later converted to sugar and then alcohol. If peat is burned while drying the grains, the whiskey will have a smoky flavour. Some distilleries have their own floor maltings ,but most use independent maltsters.

3.Mashing

At the distillery, the malt is milled to produce a coarse flour called grist. The grist is then mixed with hot water in a mashtun to extract soluble sugars. The sugar-laden water, known as wort,is piped off for use. Other unmalted grain can be combined with the grist in the mashtun for making non-malt whiskies.

3.Fermenting

The wort is mixed with yeast and heated in a washback (above). The yeast feeds off the sugars in the wort, so producing alcohol and carbon dioxide. This process, known as fermentation, lasts between 48 and 74 hours, and results in what is effectively a strong and rather tart beer, called wash.

4.Distilling

The next stage is for the wash to be distilled. Whether using a column still for continuous distillation or a pot still for batch distillation, the purpose is the same: to extract alcohol spirit from the wash.

The essential process is simple: the wash is boiled and, as alcohol boils at a lower temperature than water, the alcohol is driven off the wash as vapor; this vapor is then condensed into liquid. With pot still distillation, the spirit is condensed either in a shell‑and tube condenser or an old‑fashioned worm tub ,which produces a heavier, oilier style of spirit.

Most whiskey is distilled twice—the first time in a wash still (known as a “beer still” in the US), the second time in a spirit (or “low wines”) still. But Irish whiskey is traditionally triple distilled to create an even purer spirit.

5.The Cut

A spirit safe is used at distilleries using pot still distillation to enable the distillers to assess the spirit. The first and last parts of the “run” during the second distillation are not pure enough for use. Known as the “foreshoots” and the “feints,” respectively, they will go back for redistillation along with the “low wines” from the first distillation. The desired and usable part of the distillation, however, is the middle section, and this is known as the “middle cut,” or just “the cut”.

This usable spirit, which is called “new make,” is drinkable and exhibits some of the characteristics that will be in the final whiskey. However, it will not have achieved any depth of flavour or colour yet, and it is not allowed to be called whiskey.

6.Filling into casks

The new make will have its strength slightly reduced to about 63 or 64% ABV—the optimum strength to begin maturation.

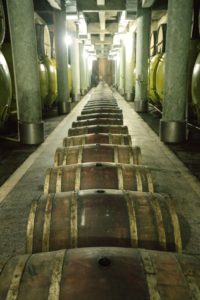

The spirit is then piped from a holding tank into oak casks (above). In the US, the spirit is filled into new, charred barrels; in Scotland, it is filled into used casks.

7.Maturation

The process that turns raw, clear, new make into the richly hued, complex-tasting drink we know as whiskey is maturation. The length of time for maturation varies, depending on climatic conditions, the size and type of the casks used, and legal requirements—at least three years for Scotch.

8.Blending

The majority of whiskey sold is blended whiskey—a mix of malt whiskey and grain whiskey. As many as 40 or more whiskies may be combined in a blend, and the art of the blender (above) is to marry flavours so that they balance and unify. Blends tend to be tailored to specific tastes and markets.

9.Bottling

The bottling of whiskey is often carried out at automated plants, but sometimes the bottling and labelling is done by hand. Most whiskey is reduced with water to a bottling strength of 40 or 43% ABV,but cask strength bottlings are released at the strength they came out of the cask (in the region of 53–65% ABV).